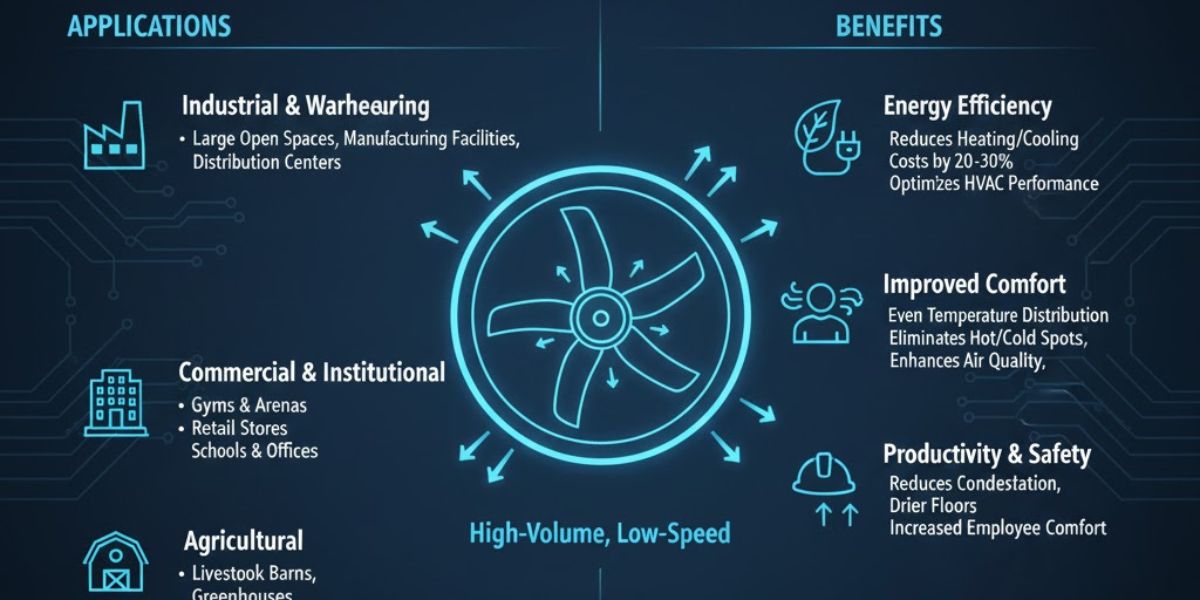

High-Volume, Low-Speed (HVLS) fans are widely used in warehouses, manufacturing plants, gyms, hangars, agricultural buildings, and other large spaces to improve airflow and thermal comfort. While these fans are mechanically simple in appearance, their electrical requirements are an essential part of successful and safe installation. Inadequate electrical planning can lead to performance issues, downtime, code violations, or safety risks. Understanding the electrical considerations before installing HVLS fans helps facility managers, building owners, and project planners avoid costly mistakes and ensure long-term reliability.

Why Electrical Planning Matters for HVLS Fans?

HVLS fans operate continuously for long periods and often in demanding environments. Their size, motor type, and control systems place specific demands on a building’s electrical infrastructure. Proper electrical planning ensures:

-

Safe and compliant operation

-

Optimal fan performance and efficiency

-

Reduced risk of electrical failures

-

Compatibility with building management systems

-

Lower maintenance and operating costs

Because HVLS fans are typically installed in large, open spaces, electrical requirements must be evaluated alongside structural, operational, and environmental factors.

Power Supply Considerations

Voltage and Phase Requirements

HVLS fans are designed to operate on specific voltage and phase configurations depending on the model and manufacturer. Large commercial and industrial fans commonly require higher-voltage power supplies and may be designed for single-phase or three-phase systems.

Before selecting an HVLS fan, it is important to confirm:

-

The available power supply in the building

-

Whether the electrical service matches the fan’s requirements

-

If electrical upgrades or transformers may be needed

Mismatch between fan requirements and available power can lead to inefficiency, increased wear, or inability to operate the fan properly.

Dedicated Circuits

HVLS fans typically require dedicated electrical circuits to ensure consistent power delivery and to prevent interference with other equipment. Shared circuits can cause voltage fluctuations, nuisance tripping, or performance issues, especially in facilities with heavy machinery or variable electrical loads.

Dedicated circuits also simplify troubleshooting and maintenance over the life of the fan.

Motor Type and Electrical Impact

Direct Drive vs. Gearbox Systems

The motor design of an HVLS fan affects its electrical characteristics:

-

Direct-drive motors often use advanced motor technology that provides smooth operation and precise speed control.

-

Gearbox-based systems may have different startup characteristics and electrical demands.

Understanding the motor type helps electricians size circuits correctly and select compatible protection devices.

Starting and Operating Loads

Even though HVLS fans operate at low speeds, motor startup can create temporary electrical loads. Electrical systems must be designed to handle both startup and continuous operation without stressing wiring, breakers, or control equipment.

Control Systems and Wiring Needs

Fan Controllers

Most HVLS fans use dedicated controllers to regulate speed, direction, and operating schedules. These controllers may be:

-

Wall-mounted

-

Integrated into a central control panel

-

Connected to a building automation system

Each control method has specific wiring and power considerations that must be planned in advance.

Integration with Building Systems

In larger facilities, HVLS fans are often integrated with:

-

HVAC systems

-

Temperature or humidity sensors

-

Building management systems (BMS)

This integration can improve efficiency but requires additional electrical planning to ensure compatibility and reliable communication between systems.

Electrical Code Compliance and Safety

Local and National Electrical Codes

All HVLS fan installations must comply with applicable electrical codes and regulations. These codes govern:

-

Wiring methods

-

Grounding and bonding

-

Overcurrent protection

-

Disconnect requirements

Codes vary by location, making it essential to work with professionals familiar with local regulations.

Disconnects and Safety Shutoffs

For safety and maintenance purposes, HVLS fans typically require a means of disconnect near the fan or control location. This allows power to be safely shut off during servicing or emergencies without affecting other systems.

Grounding and Protection

Proper grounding is critical to protect equipment and occupants. Surge protection and appropriate circuit protection devices help safeguard HVLS fans from electrical disturbances common in large industrial environments.

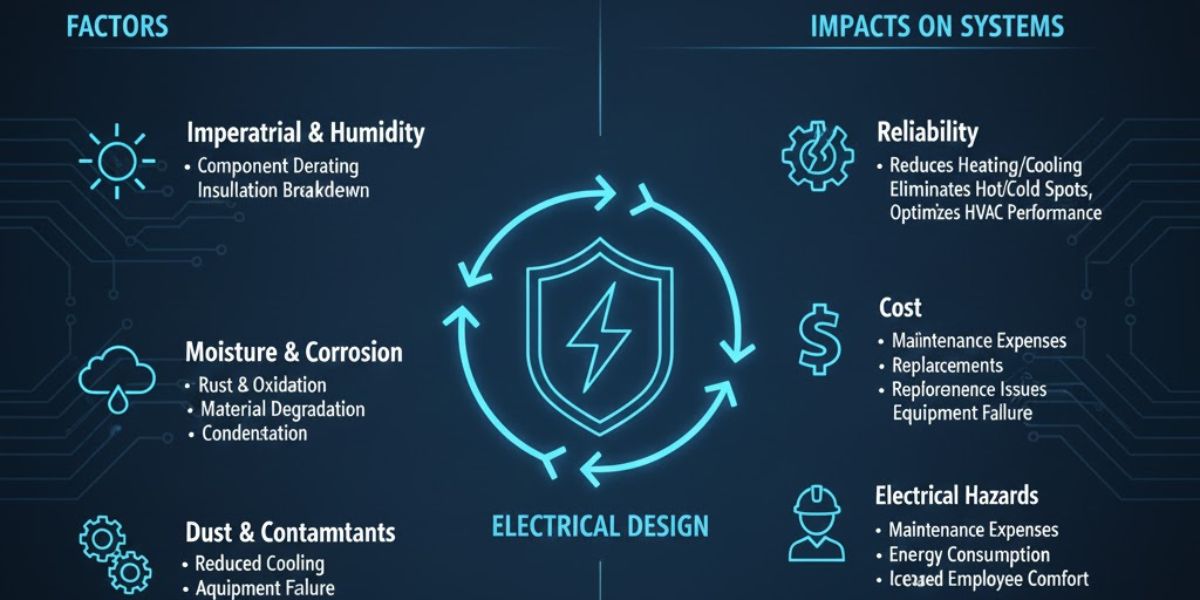

Environmental Factors Affecting Electrical Design

Temperature and Humidity

Large spaces such as warehouses or agricultural facilities may experience extreme temperatures or high humidity. Electrical components must be rated for these conditions to prevent premature failure.

Dust, Corrosion, and Moisture

Facilities with dust, chemicals, or moisture in the air require electrical enclosures and components designed to withstand harsh environments. This includes control panels, wiring methods, and connectors.

Planning for Scalability and Future Expansion

When installing multiple HVLS fans or planning future expansion, electrical capacity should be evaluated carefully. Adding fans later without adequate planning can overload electrical systems or require costly retrofits.

Proactive planning includes:

-

Assessing panel capacity

-

Allowing space for additional circuits

-

Designing controls that can support multiple fans

The Role of Licensed Professionals

Electrical requirements for HVLS fans are not a DIY consideration. Licensed electricians and qualified engineers play a critical role in:

-

Evaluating existing electrical infrastructure

-

Designing compliant electrical layouts

-

Coordinating with fan manufacturers

-

Ensuring safe commissioning

Manufacturer guidelines should always be followed, but final designs must also meet local electrical standards.

Long-Term Reliability and Maintenance

Proper electrical installation contributes directly to the longevity of HVLS fans. Clean power delivery, appropriate protection, and correct wiring reduce wear on motors and controls, lowering maintenance needs over time.

Regular inspections and preventive maintenance further ensure that electrical components remain in good condition and compliant with evolving safety standards.

Conclusion

Electrical requirements are a foundational aspect of installing HVLS fans in large spaces. From power supply and motor characteristics to control systems and code compliance, careful planning ensures safe operation and maximum performance. While HVLS fans are known for their energy efficiency and simplicity, their electrical design should never be underestimated. Working with qualified professionals like Marut Air and planning ahead protects both the investment and the people who rely on these systems every day.

Frequently Asked Questions

1. Do HVLS fans require special electrical wiring?

HVLS fans often require dedicated circuits and wiring designed to handle their specific power and control needs. Requirements vary by model and must follow local electrical codes.

2. Can existing electrical systems support HVLS fans?

In many cases, yes—but an electrical assessment is necessary to confirm capacity, compatibility, and code compliance before installation.

3. Are HVLS fans energy efficient from an electrical standpoint?

Yes. HVLS fans are designed to move large volumes of air efficiently, often using less energy than multiple smaller fans when properly installed.

4. Do HVLS fans need three-phase power?

Some models are designed for three-phase power, while others can operate on single-phase systems. This depends on the manufacturer and fan size.

5. Is a disconnect switch required for HVLS fans?

Most electrical codes require a means of disconnect for maintenance and safety. The exact requirements depend on local regulations.

6. Can HVLS fans be connected to building management systems?

Many HVLS fans can integrate with HVAC or building management systems, but this requires compatible controls and proper electrical planning.

7. How does motor type affect electrical requirements?

Motor design influences startup loads, control methods, and power quality needs, all of which must be considered during electrical design.

8. Are there special considerations for industrial environments?

Yes. Dust, moisture, heat, and corrosive conditions may require specially rated electrical components and enclosures.