Large commercial or industrial buildings, most of the owners & managers mainly focus on machinery, productivity, and the safety protocols. Whether its industrial cooling system, safety system, fans alignment, and blade balance setup. But they continuously face failures to achieve higher productivity, lower electrical bills, and reduce accidents. They can’t understand the air circulation’s silent factor in industry, which increases the operating costs of industrial operations. If you don’t think about it, you should because insufficient air circulation in industrial buildings can affect industrial operations, causing operating costs to be higher.

If you want to know more about the hidden costs of poor air circulation in industrial buildings, stay tuned with us. In this blog, we will discuss how poor air circulation makes your factory environment uncomfortable and affects workers’ health. Machine performance, energy consumption, and safety compliance. Let’s understand it:

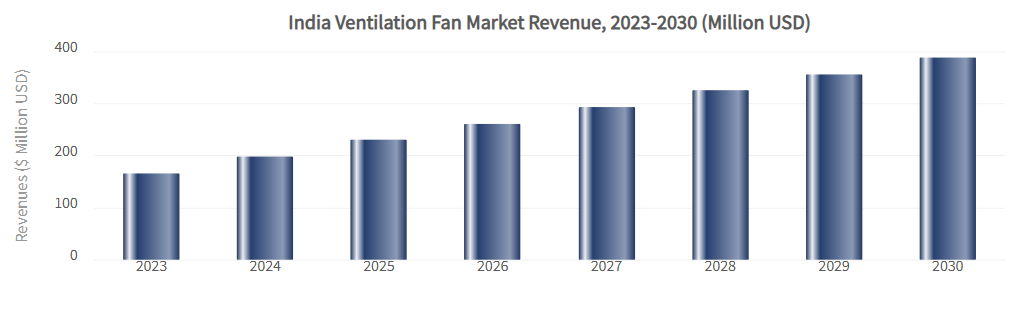

Demand For Industrial Air Circulation Market

As per the NMSC study, the Indian industrial fans market is valued at USD 167.7 million in 2023, and it is expected to reach USD 390.3 million by 2030 with a growing CAGR of 12.2 % from 2024 to 2030. The Indian commercial HVAC fans market is forecast to reach around $7020.3 Million by 2032, with a growing CAGR 8.6% from 2025 to 2032, as studied by Metastat. The industrial ventilation market is growing because of rapid industrialization, strict workplace safety, and improved quality and heat stress in the industries.

Why Air Circulation Matters For Large Industrial Buildings?

Effective air circulation is most important for every commercial & industrial building, where huge machinery operates around the clock with electrical panels and workers. Without a sufficient ventilation system, heat, dust, fumes, and humidity create an uncomfortable & unsafe working environment in a manufacturing facility. Industries that are operating with a good air circulation system not only enhance workers’ safety but also protect workers’ health, achieve higher productivity, and ensure compliance with industrial safety standards

- Air circulation reduces dirt, dust, and harmful indoor pollutants to keep the air fresh and breathable.

- A good industrial ventilation system supports machinery from overheating and maintains higher performance.

- Reduce the hazardous particles and create a comfortable environment.

- Also supports regulatory safety standards with less effort.

- A fresh, clean, and hygienic environment creates a comfortable and energized worker or machine safety.

- Proper airflow protects infrastructure and reduces the requirements of in-house maintenance.

How Does Insufficient Air Circulation Raise Hidden Costs In Industrial Buildings?

Ineffective air circulation silently enhances the hidden costs of equipment overheating, damage, and higher energy consumption for fast wear & tear. Compromised ventilation also impacts productivity, safety, and unplanned operational downtime that adds hidden expenses.

1. Heat Accumulation and Productivity Loss

Large industrial machinery produces continuous heat, fumes, or dust, and without proper ventilation, the hot air is trapped inside the large warehouse or production sheds. When you implement the large industrial exhaust fans or HVLS fans, the result is your overheated space, free from stress equipment, which reduces worker comfort and directly makes positive impacts on productivity. Because the higher indoor temperature directly impacts workers’ productivity, it increases fatigue, mostly in manufacturing plants, foundries, and metal workshops.

2. Rising Health Issues Among Workers

Insufficient air circulation can allow dust particles, welding fumes, and chemical vapours to accumulate in the large industrial sheds. Or sometimes workers can feel:

- Respiratory problems

- Headache and dizziness

- Skin or eye irritation

- Increase accident chances or health risks

Various industries like chemical plants, PVC plants, textile and dyeing industries are vulnerable when airflow is inadequate.

3. Faster Machinery Wear and Equipment Failure

Large industries are operating with dust, dirt, and humidity, and it not only affects the workers’ health, but it also makes a negative impact on machines too:

- Inadequate ventilation makes motors overheat

- Dust accumulates on the bearings or sensitive components

- It enhances the needs of maintenance.

4. Increased Fire and Explosion Risks

Some industries like chemicals and textile plants are operating with flammable gases, and poorly ventilated space is most dangerous because they increase the chances of health risk of worker’s.

- Creates a highly flammable environment

- Workers working in a flammable, hazardous environment

That’s why the safety guidelines of OSHA industrial exhaust fans help safety audits by placing a strong emphasis and providing effective ventilation, considering the movement. It means the proper airflow is not just about maintaining a comfortable environment; it also contributes to maintaining industrial safety standards.

5. Higher Energy Consumption and Operating Costs

Here is the main point: increasing hidden costs, poor air circulation, and misalignment of industrial exhaust fans actually increase the electric bills. When industrial exhaust fans don’t work properly, it leads to:

- Longer running condition

- Cooling system faces struggle

- Higher electric bills

If you implement the proper industrial air circulation system in your industry, such as HVLS fans, industrial exhaust fans, it not only impacts on worker’s productivity but also contribute for enhancing machine lifespan.

Winding Up

In large industries, poor air circulation is not a minor issue; it leads to higher operational costs, electric bills, or increased worker stress. Choosing a proper air circulation partner for your industry means energy efficiency, safety, and long-term cost-effective operational costs. Good air circulation is the smart choice of preventive investment and is suitable for every type of industrial operation.

People Also Ask About The Hidden Costs Of Poor Air Circulation In Industrial Buildings

Q.1 What are the safety risks of insufficient ventilation?

A: Inadequate airflow can enhance the chances of heat buildup, toxic fumes, accumulation, poor air quality, and accidental risks.

Q.2 How do industrial exhaust fans enhance workers’ comfort?

A: Industrial exhaust fans reduce the indoor toxic fumes and heat stress, or bring in fresh natural air. It follows the push-pull concept for smooth industrial operations.

Q.3 What are the signs that an industrial fans show it needs servicing?

A: When your industrial fans generate heavy noise, frequent shutdowns, rising heavy electric bills, or control panels technical problems. For fan control panels, you follow the simple DIY tips.