Fan control panels are the backbone of your industrial ventilation or cooling system in large industries. When your fans’ control panels stop working suddenly or are continuously beeping alarms. So, don’t panic. In most cases, the fan control panels require maintenance and some DIY basic checks, such as loose wiring and incorrect wiring connections. You don’t need to hire any professional workers; you can easily fix them. If you want to know some easy and simple DIY fixes, stay tuned with us:

In this blog, we will discuss in simple terms how to maintaine fans control panel or DIY fixes for reducing errors or downtime, get things working again, and ensure effective airflow without the stress. The large industrial fans are working with excessive heat and machinery, and providing a comfortable environment for every worker. These small fixes not only solve the issues but also recommend that you perform preventative maintenance and protect fans from long-term damage.

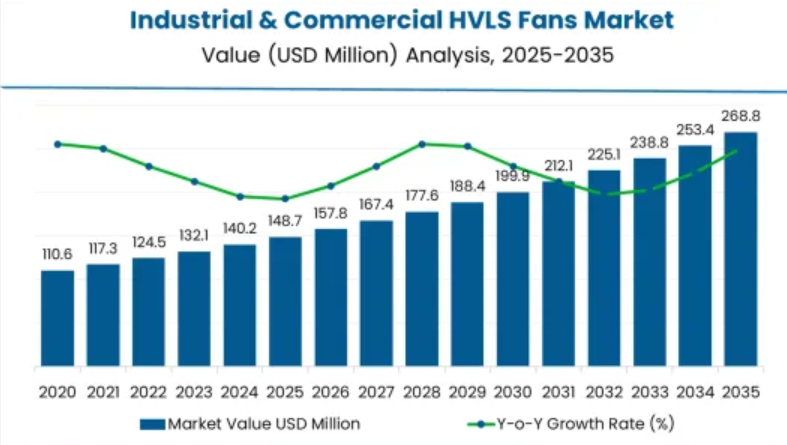

Demand for Industrial Fan Control Panels?

The industrial commercial HVLS fans market is valued at USD 148.7 million in 2025, and it is expected to grow to USD 268.8 million by 2035 with a growing CAGR of 6.1% during the forecast period 2025-2035. HVLS fans capturing the industrial cooling market approach 58.0% of the total market share in 2025. Says by Future Market Insights.

Why do fan control panels develop errors?

The industrial fans’ controllers develop errors because of electrical issues, electrical overload, or improper installation of fans. Most of the causes, such as power fluctuations, loose wiring, or overheating, can make an impact on the smart control panels. It makes a heavy impact on VFD’s malfunctions. To prevent these issues, you need to do regular inspection and servicing of the working control panels to ensure smooth airflow and energy efficiency.

What Are The Simple Diy Fixes For Common Fan Control Panel Errors?

The fan controllers work as the mind of large industrial fans, but sometimes they show some errors and stop working properly. But the main thing is you don’t need to hire any technician, because below are some simple DIY tasks that enhance safety and help your control panels work effectively. The ventilation segment led the largest revenue share of 46.1% in 2024, according to Grand View Research.

1. Check the Power Supply First

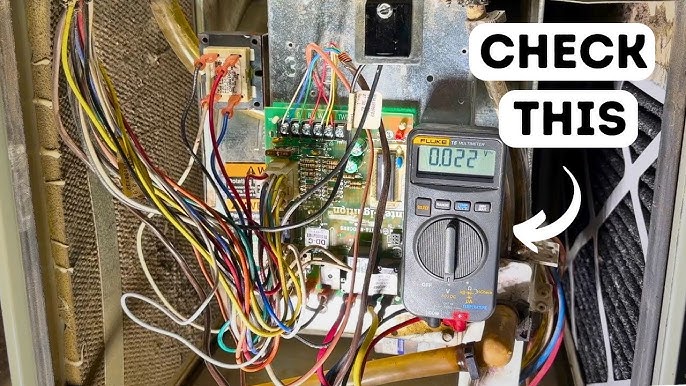

Unerupted power supply is one of the most common errors that include voltage fluctuations, tripped breakers, or loose power connections, which instantly ring alarms. You need to start checking the main power source, circuit breakdowns, and simple restoration operations.

2. Inspection Of Wiring Connection

Loose or inaccurate wiring can confuse the control panels for operating the huge industrial HVLS fans and lead to communication errors. Ensure the cut of power supply and carefully inspect the wiring terminals, insulation, or corrosion. Replace damaged or tightening connections for smooth & effective airflow.

3. Clean Dust and Dirt Buildup

When fans are operating in heavy-duty industrial environments, dust, dirt, and moisture are the silent troublemakers for your fans. Because dust or dirt can lead to overheating or advanced sensor errors. You need to regularly maintain industrial equipment fans or industrial duct coolers. Gently cleaning the control panel with dry cloths or compressed air makes the fan control panel clean andwell-maintainedd.

4. Reset the Control Panel

Continuous operating in an industrial environment, fans’ controllers need a fresh restart. When your fans’ controllers display unwanted errors, you need to restart them as per the guidelines. A simple reset easily removes the software glitches and makes it work smoothly.

5. Check Sensors and Temperature Settings

Sensors misalignment and other common causes of errors result in higher electric bills. You need to ensure the temperature sensors, pressure sensors, and speed controllers are properly positioned. Verify the fan control system requirements & incorrect parameters that trigger unnecessary alarms.

What Are The Benefits Of Choosing DIY Fixes For Common Fan Control Panels?

| Benefit | Why It Matters |

| Cost effective | DIY tips help to reduce expensive repairs or downtime |

| Analyse errors | Minor fan control panel issues can be fixed instantly |

| Easy Maintenance | Helps you understand and maintain your system better |

| Reduced industry Downtime | Fans get back to working faster without long delays |

| Enhance Safety Awareness | Teaches basic electrical safety and panel handling |

| Increase Panel Life | Detecting errors and fixing them can reduce the chances of costly repairs |

Conclusion:

To conclude this topic, the commercial HVLS fans operate around the clock in harsh industrial environments, which makes control panels an essential part for smooth or energy-efficient operations. Errors in control panels can lead to sudden breakdowns and less uninterrupted industrial operations. In this blog, we discussed the simple & smart DIY tips for resolving issues of fan control panels.

People Also Ask: Simple DIY Fixes For Common Fan Control Panel Errors

Q.1 why fan control panels important for large commercial facilities?

A: HVLS fans controllers are easy to manage the airflow with energy efficiency, ensuring efficient, safe, and reliable ventilation in large facilities.

Q.2 What are the applications of fan control panels?

A: The smart fan controllers are used in factories, warehouses, manufacturing plants, and commercial corporate offices for smooth ventilation or airflow.

Q.3 Do fan control panels provide an exact indoor temperature?

A: The smart control panels regulate airflow by optimizing fan speed and provide a comfortable working environment across the facility.

Q.4 How does it adjust fans speed automatically?

A: fan control panels working with AI learning or temperature sensors technology, they analyze the industry’s indoor environment and automatically adjust fan speed to maintain temperature.