One type of ventilation fan, specifically designed for mounting inside circular air ducts, is the circular inline fan. In contrast to conventional wall or ceiling fans, these fans are positioned inline or in the center of the ductwork and pull or push air through it to maintain a building’s healthy airflow. Thanks to their round, compact shape, they fit perfectly into small spaces and duct systems of all sizes.

Which Applications Make Circular Inline Fans Useful?

There are many applications for circular inline fans, which are very adaptable.

It removes moisture and unpleasant odors from bathrooms and toilets to prevent mold and mildew. Use kitchen exhaust fans to remove heat, smoke, and cooking fumes, especially in homes and restaurants.

- Laundry Rooms: To maintain fresh air and regulate humidity.

- Cafeteria and Dining Areas: To keep visitors’ air clean and comfortable.

- Offices and Commercial Spaces: To ensure a healthy working environment through general ventilation.

- Industrial Areas: Used to eliminate dust fumes and surplus heat in factories or workshops. HVAC systems are integrated into heating, ventilation, and air conditioning systems to distribute air efficiently. Hotels should install them in the kitchens, restrooms, and guest rooms for constant air quality.

- Damp or Humid Environments: Because of their design, they can function effectively even in high-humidity environments like spas or basements.

The Internal Workings Of A Circular Inline Fan.

It’s easy to comprehend how a circular inline fan operates.

Air Intake: A circular duct houses the fan. Air is drawn from one end of the duct when turned on.

Impeller Action: An impeller, which resembles a propeller, spins inside the fan; an electric motor powers this impeller, which is made to move air effectively. The impeller’s rotation generates a pressure differential that forces air through the duct and to the opposite side. This facilitates the removal of stale air from the area or the circulation of fresh air. Most contemporary fans have motors protected by features like thermal overload cut-off, which prevents overheating and easy damage.

Noise Reduction: The fan can run quietly in homes and offices thanks to its low noise levels caused by its design and casing. Some circular inline fans combine the advantages of centrifugal (high pressure) and axial (straight airflow) fans with a mixed flow design. This implies they can move a lot of air quietly and efficiently even through lengthy or complex duct systems.

Important Characteristics Of Circular Inline Fans.

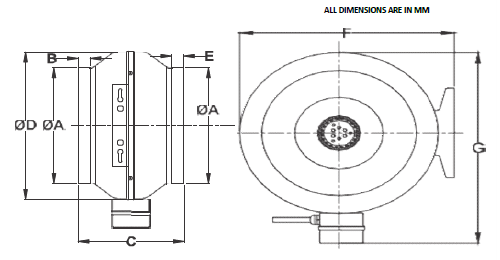

Circular inline fans are popular because of the following notable features. They save space in walls and ceilings because their inline round design fits easily inside ducts.

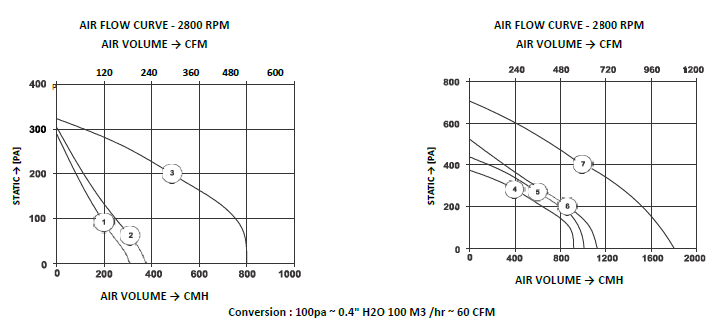

High Airflow and Pressure: Able to move large amounts of air even against resistance or through long ducts. Low noise levels: These devices are ideal for homes, workplaces, and hotels because they are specifically made to operate quietly.

Durable Construction: Housings are typically constructed from premium plastic or galvanized steel, giving them a long lifespan and rust resistance. Available in a wide range of diameters, usually between 100 and 315 mm, to accommodate a variety of duct sizes and airflow requirements, this product offers a wide size range.

Motor Protection: For safety and dependability, motors are typically rated IP44, which protects them from dust and water splashes, and they have thermal overload protection. Easy Installation and Maintenance: This product is made to be mounted quickly and easily accessible for cleaning or repairs.

Energy Efficient: Many models are made to use less electricity and still function well.

Accessories Available: For extra safety and versatility, consider options like grille, speed controllers, and back-draft shutters, which stop air from flowing backward.

In conclusion, circular inline fans are an intelligent, dependable, and efficient option for ventilation in various settings, including homes, workplaces, hotels, and factories. They are a favorite among builders and homeowners because of their robust performance, quiet operation, and straightforward design. A circular inline fan may be ideal for your needs, whether you want to regulate humidity, enhance air quality, or simply maintain a comfortable environment.

The Most Common Queries About Circular Inline Fans.

Question 1: What is the best way to pick a circular inline fan that fits my space?

Answer: Select a fan by considering the airflow (measured in CFM or m³/h) required for your room and the diameter of your duct. Higher capacity fans are required for larger spaces or longer ducts.

Question 2: Do circular inline fans make noise?

Answer: No, nowadays the majority of circular inline fans are made to be silent. They are appropriate for quiet spaces like offices and bedrooms because they use special casings and impellers to reduce noise.

Question 3: Can a circular inline fan be used in humid spaces like the kitchen or bathroom?

Answer: Humid environments frequently use these fans. They use materials resistant to corrosion and rust, and their motors are shielded from moisture.

Question 4: Do circular inline fans need to be maintained regularly?

Answer: Generally speaking, these fans require little upkeep. To maintain peak performance, cleaning the impeller and inspecting the duct for any obstructions or dust accumulation every few months is a good idea.

Question 5: Do these fans use a lot of energy?

Answer: In general, circular inline fans are more economical for long-term use because they use less power while still producing powerful airflow.

Question 6: What materials are used to make circular inline fans?

Answer: Depending on the size and model, the impeller may be made of metal or plastic, while the housing typically comprises high-quality plastic or galvanized steel.

Question 7: Is it possible for me to install a circular inline fan myself?

Answer: Although installation is simple for individuals with rudimentary do-it-yourself skills, it is advised to have a professional handle the electrical connections and mounting for optimal results and safety.