Every industrial warehouse built for storing finished goods enhances movement and productivity, but most of the facility managers or owners ignore the air quality & ventilation, which they should not because insufficient air quality is a major problem in every industry or warehouse. Poor ventilation in warehouses not only makes the space uncomfortable, but it also increases the energy costs, spoils the quality of finished goods, reduces worker productivity, and creates higher safety risks. If you are wondering about how to make your industrial warehouse have good ventilation, you are on the right track.

In this article, we will discuss the 7 clear signs that disturb your warehouse ventilation and cost-effective solutions for enhancing productivity without affecting comfort.

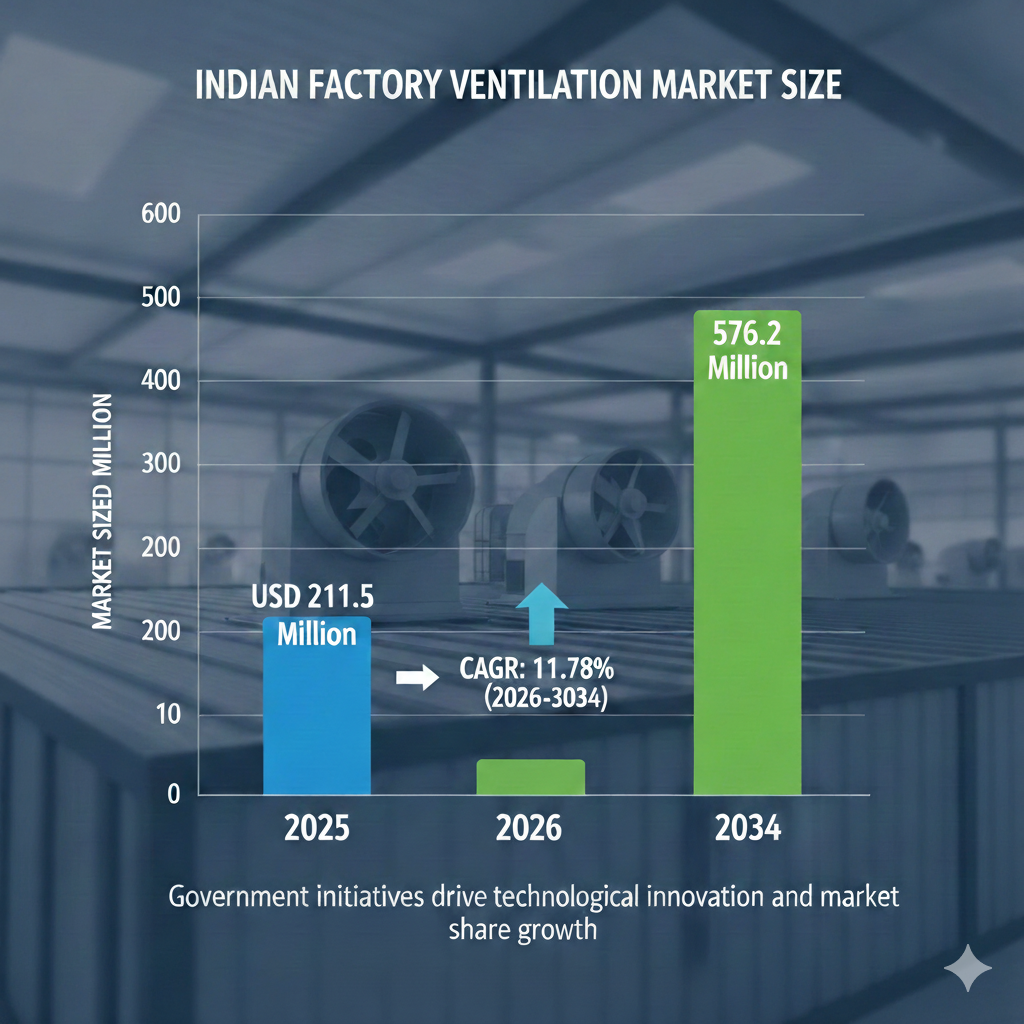

Demand For The Industrial Ventilation System In India?

As per the study by IMARC Group, the Indian factory ventilation market size is USD 211.5 Million in 2025, and it is estimated to reach USD 576.2 Million by 2034 with a growing CAGR of 11.78% during 2026-2034. The Indian government also makes efforts for technological innovations in industrial ventilation systems and increasing the share of the factory ventilation system market.

Why Do Industrial Warehouses Need Better Ventilation?

Every industrial warehouse has a large storage capacity and is built with metal sheds, and metal easily reacts with sun contact, which is why they need to maintain a safe, effective, or productive environment. Poor ventilation traps dust, fumes, heat, and moisture that cause it damages machinery with higher energy operating costs and can lead to serious health issues for workers. An effective ventilation system allows for maintaining regular indoor temperature, removes airborne contaminants, and improves the overall air quality, enhancing workers’ comfort & employees’ efficiency.

Why Ventilation Matters?

- Prevents heat buildup and maintain the stable indoor environment

- Easily control dust, fumes, and airborne contaminants

- Ventilation reduces the safety hazardous risks by poor air quality

- Helps to protect machinery from overheating

- Supports machinery or productivity in large spaces.

What Are The 7 Signs That Your Warehouse Needs Better Ventilation?

The ventilation system plays the most important role in maintaining indoor air quality, temperature control, and enhancing workers’ safety in large industrial spaces. Poor ventilation disturbs the large space or has an impact on equipment, employees’ health, or industrial operations. That’s why understanding the early signs of inadequate ventilation is important to manage & prevent long-term issues for a safe working environment.

Below, we mentioned the 7 key signs that indicate your warehouse needs better ventilation.

1. Poor Indoor Air Quality

Poor indoor quality is the most common indicator that shows your warehouse, industry, and commercial facility needs better indoor air quality. When sufficient air is not maintained properly, it contains carbon dioxide (CO₂), airborne pollutants, and volatile organic compounds (VOCs) that accumulate inside the warehouse, impacting workers’ health, raw materials, or finished goods.

It Leads To:

- State of heavy air

- Reduce oxygen levels

- Enhance heat exposure to reduce industrial emissions.

Installing a proper ventilation system or choosing the right industrial cooling partner like Marut Air means ensuring a proper air exchange rate and removing contaminated air consistently.

2. Excessive Heat and Temperature Imbalance

Industrial warehouses operate with heavy-duty machinery without taking rest, which is why their environment is full of heavy heat due to industrial machinery, industrial lighting systems, and the continuous operations of human activity. Without a ventilation system, heat becomes trapped, and it leads to uneven temperature distribution.

Poor Temperature Indicates:

- Poor airflow

- Heavy heat and dust

- Higher chances of workers’ fatigue and heat disturbance for machinery.

- Heat circulation

- Enhance fatigue or heat dissipation mechanisms

3. Lingering Odors and Chemical Smells

Warehouse indoor environments have persistent odors and show strong signs of air contaminants that are not being removed effectively. Warehouses which are operating with packaging materials, fumes, or industrial goods are especially vulnerable.

Odor Buildup Shows Signs:

- Insufficient indoor ventilation

- Lack of fresh air supply

- Insufficient contaminants removal

The ventilation system & industrial exhaust fans are especially designed to eliminate odors or improve indoor air quality.

4. High Humidity and Condensation

High heat & moisture buildup can show you insufficient airflow or humidity control. Walls, ceiling, and heating metal surfaces also show you secondary issues.

Its causes include:

- mold & mildew growth

- Corrosion of equipment

- Damaged or stored inventory.

5. Dust Accumulation and Particulate Matter

The industrial warehouse and factory environment is full of dust, heat, and excessive noise, and dust particles easily settle on the machinery. These dust particles affect industrial machinery and increase the health or downtime risks.

- Packaging material

- Raw material handling

- mechanical operations

6. Employee Health and Comfort Complaints

Insufficient ventilation in the industry also makes a heavy impact on the workers’ health and safety compliance. Those employees who work in poorly ventilated space they feels:

- Fatigue

- Headaches

- Dizziness

- Respiratory risks

7. Increased Energy Consumption

Unexpected or unexpected electricity bills that show your industrial ventilation system is not working properly. Because the industrial ducted air cooler or other cooling system struggles to cool your industry.

Properly Optimized Ventilation Improves:

- Less electric costs

- Higher system performance

- Operational costs

Winding Up

By the essence of this topic, industrial warehouse ventilation is all about maintaining a comfortable environment, removing dust, heat, and odors. It works effectively and ensures the safety of raw materials. Choosing the best industrial ventilation company helps your industry achieve higher productivity levels without increasing costs.

You can also read: Why Factories and Warehouses Overheat Faster Than You Think

People also ask about 7 Signs Your Warehouse Needs Better Ventilation.

Q.1 how ventilation enhance worker productivity in cement plants?

A: A proper ventilation system enhances workers’ productivity by removing heat, dust, fumes, and ensures workers stay healthier, focused, and more productive.

Q.2 How does the ventilation system help to protect my material in cement plants?

A: The industrial ventilation system protects cement material because it reduces dust and moisture and prevents contamination.

Q.3 Is an industrial ventilation system cost-effective for every industry?

A: The industrial ventilation system is a cost-effective solution for every industry because it requires less energy, less maintenance, and helps to enhance worker productivity.